Making the invisible visible

X-ray analytics for research and industry

From a lorry right down to a molecule

The new Empa center has set itself the goal of further developing X-ray methods with the aim of strengthening developments in the field of materials research. Scientific and industrial innovation will be supported across the whole range of resolutions and sample sizes; this is now possible with everything from lorries down to individual molecules. For example, Mathieu Plamondon can inspect what is being transported in a lorry without actually having to climb into it. The Empa researcher uses the high-energy linac CT system to verify whether the lorry is carrying cigarettes, water or bicycles. The resolution extends down to the millimetre range, so that even a bicycle spoke behind a water tank is visible.

Rolf Kaufmann is responsible for applications involving smaller objects, for which higher resolutions are needed. With his micro-CT scanner, he can put bones or the wood cells of a violin under the microscope. He will soon have an additional device called a nano-CT scanner in his laboratory, which will reach a resolution of up to 300 nanometres. And Antonia Neels can achieve even higher resolutions with the SAXS, WAXS and XRD devices. She can, for example, determine the arrangement of cellulose fibres in wood, nanostructures on surfaces and even molecular structures. It is possible to go even further at the PSI: even individual molecules can be detected with its synchrotron. A device with a still higher resolution is currently under construction; the 800-metre-long SwissFEL is expected to go into operation at the end of 2016.

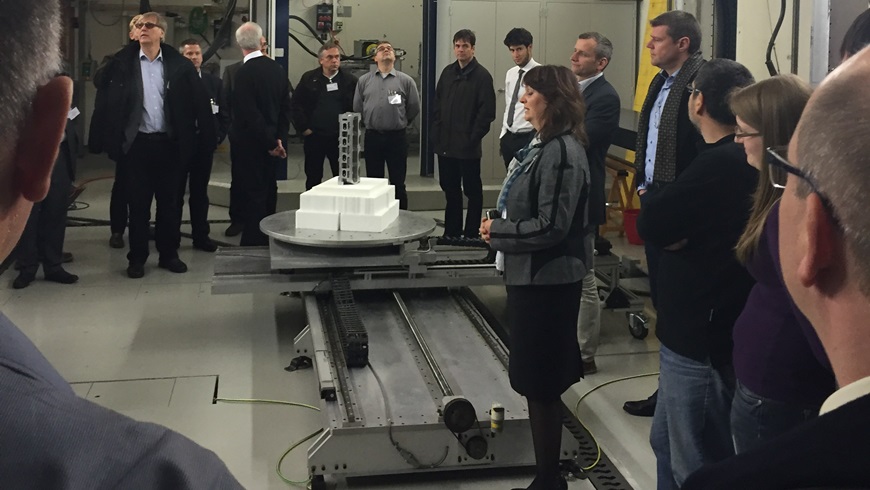

But the X-ray center at Empa has another specialist area: Michele Griffa makes 3D simulations from X-ray images, enabling him to distinguish between different materials. For example, with recycled concrete, he can determine how much of this comes from used concrete. This is important because if the recycled material accumulates too much in one particular area, the concrete will no longer be strong enough.

If you have a Yahoo account, you can download images here .

You can download the images or a zip-file with images here.

Further information

Dr. Antonia Neels

Center for X-ray Analytics

Phone +41 58 765 45 07

Editor / Media contact

Cornelia Zogg

Empa, Communications

Phone +41 58 765 44 54

-

Share